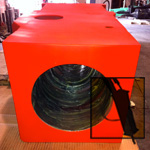

Cracked Heads

Cracked Heads

Due to dry firing, prying, or improper use.

Not A Problem!!

At Hydraulic Breaker Services we specialize in refurbishing cracked front heads, whether just small hair line cracks or completely cracked in two. We also stock a wide range of used and rebuilt tool holders and front heads.

Explanation of Program

Shortly after arrival, your breaker is disassembled and fully inspected. A detailed estimate of parts and services is prepared and sent to you for your approval. Once authorized to proceed, we typically have the breaker ready to ship back to you in 5-7 working days.

Breaker reconditioning includes the following:

- The main body is removed from the outer bracket and separated into front tool holder section, N2 (back cap) section and cylinder sections. Many cylinder sections include an accumulator – this is removed from the cylinder and put aside for inspection analysis.

- After removal of all interior and exterior components from the cylinder section, the original factory machining access plugs are removed and the cylinder section is sent out to be dipped. Removing the machining access plugs insures that no contamination remains lodged in the internal passages (most shops rebuilding breakers do not thoroughly cleanse the cylinder section therefore future seals life is shortened). After return to our shop, new access plugs are installed in the cylinder section and it is ready to be rebuilt.

- All new seals are added to the cylinder body, control valve body and BPM adjuster case assemblies and the piston and upper seal carriers are reinstalled. At this point the original piston has been inspected and either reworked per factory service procedures or replaced with a new one. The main body accumulator, having been inspected and rebuilt with a new bladder, is reinstalled on the main cylinder and new upper and lower bushings have been installed in the tool holder section. N2 section, cylinder section and tool holder sections are reassembled and all fasteners are brought up to factory torque specs. Machinery quality paint is applied.